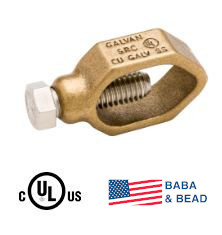

- >UL listed for copper-bonded, galvanized, and stainless steel ground rods.

- UL listed for #4, #5 and #6 rebar.

- UL listed for direct burial in earth and concrete with a stainless steel bolt.

- Performs the functions of economy, standard duty, heavy duty, and extra heavy duty.

- Able to withstand torque in excess of UL 467 requirements of 150 in/lb

- RUS listed.

- Made in USA.

| ONE CLAMP FITS 1/2, 5/8 AND 3/4 ROD DIAMETERS. | |||||||

|---|---|---|---|---|---|---|---|

| CATALOG NUMBER | Ground Rod Size, Inches | Rod Diameter Metric (Approx.) | Rebar Size | Wire Range AWG No. (CU) | Carton & Master Pack | Wt. Per 100 lb (kg) | NAED UPC No.632591- |

SRC | 1/2 (0.500) to 3/4 (0.75) For Copper-Bonded, Galvanized and Stainless Steel | 12.8 mm to 17.3 mm | #4 (1/2 inch) #5 (5/8 inch), #6 (3/4 inch) | 10 AWG - 1/0 | 50/400 | 16 (7.3) | 61344-6 |

SRC | 3/4 F (0.750 - 0.765) Full Size Galvanized | 19.1 mm | 10 AWG Solid - 2 AWG Solid, 8 AWG Stranded - 1 AWG Stranded | ||||

- UL listed for copper-bonded, galvanized and stainless steel ground rod stamped on the clamp.

- UL listed for #4 1/2-inch rebar.

- UL listed for direct burial in earth and concrete with a stainless steel bolt.

- Cast copper alloy body with hex head bolt provides simple trouble-free connection at low cost.

- Able to withstand torque in excess of UL 467 requirements of 150 in/lb.

- Made in USA.

| CATALOG NUMBER | Ground Rod Size, Inches | Rod Diameter Metric (Approx.) | Rebar Size | Wire Range AWG No. (CU) | Carton & Master Pack | Wt. per 100 lb (kg) | NAED UPC No.632591- |

|---|---|---|---|---|---|---|---|

G-5 | 1/2 (0.500) to 5/8 (0.625) For Copper-Bonded, Galvanized and Stainless Steel | 12.8 mm to 15.9 mm | #4 (1/2 inch) | 10 AWG - 2 AWG | 50/400 | 10 (4.5) | 70708-4 |

G-5 | 5/8 UL Galvanized (0.539 to 0.555) | 14.2 mm | 10 AWG - 2 AWG | ||||

G-5 | 5/8 F Full Size Galvanized (0.625 - 0.640) | 15.9 mm | 10 AWG Solid- 2 AWG Solid, 10 AWG Stranded- 3 AWG Stranded |

| Catalog Number | Rod Diameter | Rod Diameter (metric) Approximate | Conductor Range | Sub & Master Pack | Wt. per 100 lb (kg) | NAED UPC No.632591- |

|---|---|---|---|---|---|---|

G-3 (Non UL) | 3/8" | 9.5 mm | 4 Str. - 10 Sol. | 100 / 800 | 6 (2.7) | 70706-0 |

G-4*(Use G-5) | 1/2" | 12.8 mm | 2 Str. - 10 Sol. | 100 / 800 | 9 (4.1) | 70707-7 |

G5P*(Tin Plated) | 5/8-1/2" | 12.8mm to 14.2mm | 2Str. - 10 Sol. | 50 / 400 | 10 (4.5) | 61220-3 |

G-6*(Use SRC) | 3/4" | 17.3 mm | 2 Str. - 10 Sol. | 50 / 400 | 11 (5.0) | 70709-1 |

*-These items UL and CSA Listed in US and Canada for direct burial in earth and concrete.-The G-6 fits all 3/4-inch diameter rods regardless of actual or nominal diameter.

- Made from 301 stainless steel

- UL-Listed and marked for copper-bonded, galvanized, and stainless steel ground rods; also for #4, #5 and #6 (1/2″, 5/8″ and 3/4″) rebar

- UL-Listed in US and Canada for direct burial in earth and concrete

- One size fits all

- Patent pending

- Made in USA.

| One Clamp Fits 3/8, 1/2, 5/8 and 3/4 Rod Diameters. | ||||||

|---|---|---|---|---|---|---|

| Catalog Number | Rod Diameter | Rod Diameter (metric) Approximate | Conductor Range | Sub & Master Pack | Wt. per 100 lb (kg) | NAED UPC No.632591- |

SRC-SS | 3/8", 1/2", 5/8", 3/4" | 9.5 mm, 12.8 mm, 14.2 mm, 17.3 mm | 1/0 Str. - 10 Sol. | 100 | 9 (4.1) | 61499-3 |

Note: When used with stainless steel ground rods, the wire range is #8 solid to #2 stranded.

Break-Away Ground Rod Clamp

- Ideal for tamper-resistant applications

- UL Listed for Direct Burial

- Stainless steel break-away bolt

- Silicon Bronze Body

- Torque Level: Min /max 15-20 ft/lbs.

| Catalog Number | Rod Diameter | Rod Diameter (metric) Approximate | Conductor Range | Sub & MasterPack | Wt. per 100 lb (kg) | NAED UPC No.632591- |

|---|---|---|---|---|---|---|

| G31-TA | 5/8"-1/2" | 12.8 mm to 14.2 mm | 10 - 1/0 AWG | 50 / 400 | 10 (4.5) | 61536-5 |

Heavy-Duty Ground Rod Clamps (Hex-Head)

- Bronze alloy or stainless steel hardware both UL listed approved for direct burial in earth and concrete.

- Ground connection is secured by long bearing surface of clamp on ground wire.

- High-strength corrosion-resistant copper alloy. All Heavy Duty clamps UL Listed for direct burial in earth and concrete.

- UL listed for copper-bonded, galvanized and stainless steel ground rods.

- Made in USA.

| Catalog Number | Rod Diameter | Rod Diameter (metric) Approximate | Conductor Range | Sub & Master Pack | Wt. per 100 lb (kg) | NAED UPC No.632591- |

|---|---|---|---|---|---|---|

JAB12H | 1/2" | 12.8 mm | 2 Str. - 10 Sol. | 100 / 800 | 12 (5.4) | 70715-2 |

JAB58H | 5/8" | 14.2 mm | 1/0 Str. - 8 Sol. | 50 / 400 | 13 (5.9) | 70716-9 |

JAB58HH* | 5/8" | 14.2 mm | 1/0 Str. - 8 Sol. | 50 / 400 | 14 (6.4) | 61311-8 |

JAB58HP | 5/8 | 14.2 mm | 1/0 Str. - 8 Sol. | 50 / 400 | 13 (5.9) | 61502-0 |

JAB34H | 3/4" | 17.3 mm | 1/0 Str. - 8 Sol. | 25 / 250 | 15 (6.8) | 70717-6 |

JAB34HH | 3/4" | 17.3 mm | 3/0 Str. - 8 Sol. | 25/ 200 | 17 (7.7) | 61495-5 |

JAB1H | 1" | 25.4 mm | 4/0 Str. - 8 Sol. | 50 / 400 | 25 (11.3) | 70718-3 |

*-HH represents “Heavy duty hex head design screw 1/2” – 13 threads with 9/16” hex head-These items UL and CSA Listed except for JAB58HH and JAB34HHJAB58H Listed for US and Canada – 7/16 -14 threads-P designates tin plated

Type DGC Drive-On Ground Clamp

| Catalog Number | Ground Rod Diameter | Rod Diameter (metric) Approximate | Pieces/ Cartons | WT/C lb (kg) | Ground Wire Size | NAED UPC No.632591- |

|---|---|---|---|---|---|---|

| DGC-5844* | 5/8 (0.555 - 0.565) | 14.2 mm | 25 | 20 (9.1) | 1 or 2 - #4 Sol. | 61329-3 |

| DGC-5846 | 5/8 (0.555 - 0.565) | 25 | 20.0 | 1 or 2 - #4 or #6 Sol. | 61522-8 |

• For use on all 5/8″ diameter UL Listed copper-bonded ground rods.

• Used to bond one or two, #4 or #6, solid copper conductors respectively.

• Produced from high-strength copper alloy, the same material as UL Listed “acorn” type ground rod clamps.

• May be used effectively for direct-burial applications.

• To install, the only required tool is a hammer. Compression forces maximize the “direct” surface-to-surface copper contact between conductor and ground rod electrode.

• A drive-head should be used during installation of the ground rod electrode into the soil, thus minimizing any possible mushrooming or deformation on the drive (or chamfer) end of the rod. This will improve ease of installation of the drive-on clamp.

• This design places the grounding conductor in “direct” contact with the ground rod, thereby eliminating multiple paths for the current to follow, which could contribute to increased resistance.

TO INSTALL:

• Select the proper connector from the above chart.

• Drive the ground rod electrode to the proper depth per national or local code recommendations.

• Position connector and ground rod conductors as shown in middle illustration.

• Drive connector onto rod until top of connector is flush with top of ground rod as shown in adjacent illustration. Galvan suggests using a 20-ounce hammer.