MAY 2024

Q: “I recently bought 1/2-inch copper-bonded ground rods at a local distributor and noticed that the tips of the rods were painted orange. Why is this?”

Answer:

The rod tips are painted to prevent a problem. The orange paint on the tip is a color code that indicates to the wholesaler that this is a 1/2-inch diameter UL-listed rod. Color-coding is an idea that was initially brought to our attention by electrical wholesalers that were inadvertently shipping ½” x 8′ copper-bonded rods for 5/8″ x 8′ rods, and vice versa. Visually, there is little difference.

As you can imagine, this caused havoc when the computer indicated one or the other was available and none were in stock. With color-coding in place the problem disappeared almost immediately.

We introduced color-coding to all our ground rods in 2006 to help minimize or eliminate order fulfillment errors. Now wholesalers can tell different rod diameters apart in a single glance. No calipers required, no squinting necessary, no worries in the warehouse or in the field.

Color-coding continues to grow in popularity because is solves a problem. If you’d like to see the color-code scheme for all Galvan ground rods, you can find it in our Color-Coding document available on the web site from our Downloads page.

Thanks for your question. We hope you find this answer helpful.

Got a grounding electrode, clamp or connector question you’d like to ask? We’ve got answers!

We’ll get back to you with an answer ASAP. And your question could be featured on this page or in our next e-newsletter!

March 2024

Q: “The Build America, Buy America Act says no federal funds can be used for a BIL infrastructure project unless all iron, steel, manufactured products, and construction materials are produced in the United States. Do Galvan ground rods and clamps meet this requirement?”

Answer:

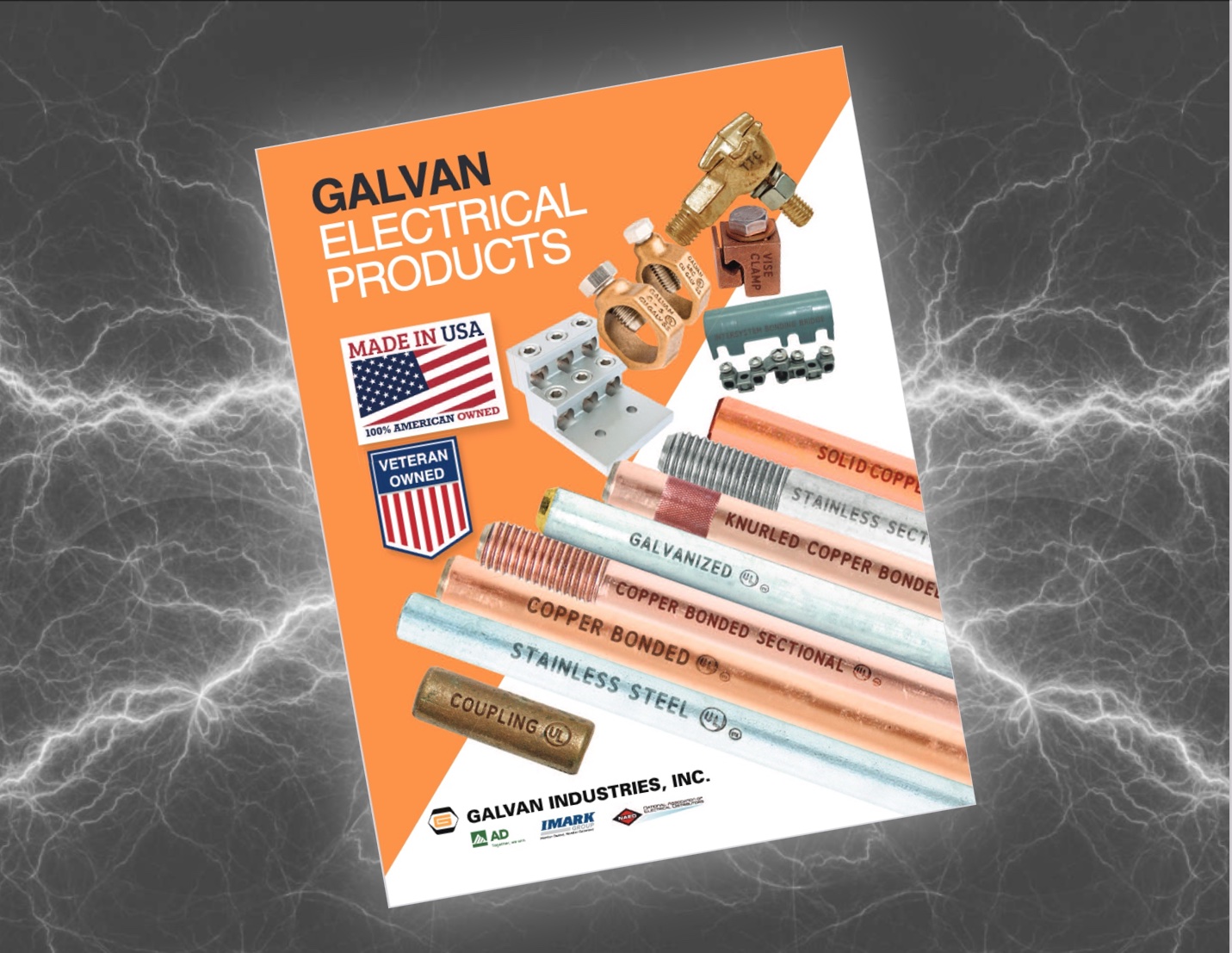

Yes, they do. The 2021 Bipartisan Infrastructure Law (BIL) included extensive new requirements for infrastructure projects to be “made in America.” Known as the Build America, Buy America Act (BABAA), this section of the law is meant to stimulate American manufacturing and create jobs for American workers.

For steel products, like ground rods, the law states “All manufacturing processes, from the initial melting stage through the application of coatings, occurred in the U.S.” Even under this high standard, all Galvan ground rods meet Buy American requirements. Our customers also avoid overseas shipping disruptions, such as those happening now around the Suez Canal.

Galvan is your reliable source for American-made, UL-listed grounding products, including:

Thanks for your question and for thinking of Galvan.

- Copper-bonded ground rods

- Solid copper ground rods

- Galvanized ground rods

- Stainless steel ground rods

- Threaded copper-bonded rods

- New Knurled copper-bonded rods

- Threaded stainless steel rods

- Pigtail ground rods

- SRC and G-5 universal ground rod acorn clamps

- Threaded and threadless couplings

- Steel grounding plates

- Ground rod drivers

The Galvan grounding products listed above are all made in the USA from US materials. We are happy to issue BABAA certificate letters specifically for and with our American-Made Galvan electrical products.

Thanks for the question. We hope you found this answer helpful.

Got a grounding electrode, clamp or connector question you’d like to ask? We’ve got answers!

We’ll get back to you with an answer ASAP. And your question could be featured on this page or in our next e-newsletter!

November 2021

Q: “Does the NEC approve of a pipe clamp being used to connect a grounding conductor to a ground rod, instead of an acorn clamp?”

Answer:

The answer depends on whether the pipe clamp in question is listed for that purpose. According to code, the GEC “must terminate to the grounding electrode by exothermic welding, listed lugs, listed pressure connectors, listed clamps, or other listed means.” Most regular water pipe clamps are not listed for use with ground rods. A pipe clamp like the Galvan JRD which IS listed for use with pipe, rebar and ground rods would meet code requirements.

In addition, the clamp must be listed for use with the materials of the grounding electrode, such as copper-coated, galvanized and/or stainless steel ground rods.

Also, since ground rods are driven below grade and their GEC terminations are buried, the clamp being used must be listed for direct burial. Ground clamps listed for direct burial are typically made from brass or bronze. The JRD, constructed from bronze alloy and stainless-steel screws is listed for direct burial in earth or concrete and would meet this requirement. Again, however, most regular water pipe clamps would not.

If you want to use a pipe clamp as a substitute for an acorn clamp, just make sure it has the proper listings. And, as always, check with your local AHJ to be certain of the rules in your area.

Thanks for the question. We hope you found this answer helpful.

Got a grounding electrode, clamp or connector question you’d like to ask? We’ve got answers!

We’ll get back to you with an answer ASAP. And your question could be featured on this page or in our next e-newsletter!

NOVEMBER 2020

Q: “Will ground rod prices remain stable in 2021?”

Answer:

That’s a great question. The answer is unknown at this point, but if costs continue to rise on the metals used to make ground rods, price increases may be inevitable.

Steel, copper and zinc prices have been going up rapidly for several months and are expected to continue climbing into 2021.

Steel prices in the United States and Europe have jumped over the past several months. as economies recover and demand picks up. in China , steel prices have risen 37% since April. Steel demand is being fuelled by a global revival of industrial production, with JP Morgan’s global manufacturing purchasing managers’ index touching a 21-month peak in August.

Also in August, copper prices rose above $3 a pound for the first time in more than two years. Today, just three months later, it is more than $3.50 per pound.

Prices for the zinc used in galvanized ground rods reached a 16-month high of $2,526 per ton September. Today it is selling at $2,674 per ton.

At Galvan it is our goal to maintain our current pricing for as long as we can, but all manufacturers will be forced to raise prices at some point if the cost of materials continues to increase.

Got a grounding electrode, clamp or connector question you’d like to ask? We’ve got answers!

We’ll get back to you with an answer ASAP. And your question could be featured on this page or in our next e-newsletter!

JANUARY 2020

Q: “Is there a safer alternative to exothermic welding for a secure, non-mechanical connection between the ground rod and the GEC?”

Answer:

Yes. Galvan pigtail ground rods are exactly that. They provide a permanent, corrosion free bond between the ground rod and the grounding conductor without the use of a mechanical clamp or the safety hazards associated with exothermic welding. The ground rods are available as either copper-bonded or hot-dip galvanized in a variety of diameters and lengths. Code compliant copper wire – solid or stranded – is brazed to the rod at the factory.

The result is improved safety and faster installation. Installers don’t have to worry about burns or inhaling chemical fumes from the welding process, and there’s no need to assemble molds or welding apparatus in the field.

Thanks for your question. We hope you find this answer helpful.

Got a grounding electrode, clamp or connector question you’d like to ask? We’ve got answers!

We’ll get back to you with an answer ASAP. And your question could be featured on this page or in our next e-newsletter!

NOVEMBER 2019

Q. “Can an Intersystem Bonding Termination (IBT) be used to bond items other than communication systems?”

Answer:

According to NEC 2014 and 2017, an IBT is for use only in bonding communications systems and cannot be used for bonding anything else. In the 2014 edition, the IBT was the only bonding method permitted for bonding communication systems.

However, a change in the 2017 edition of the code allows for the use of “other means”, specifically copper or aluminum bus bars a minimum of 1/4 inches thick and 2 inches wide with “sufficient length to accommodate at least three terminations for communications systems in addition to other connections.” All connections to the busbar must be made with a listed connector.

“If aluminum busbars are used, the installation shall also comply with 250.64(A),” NEC 2017 states.

Using a busbar as described would allow for other bonding connections to be made together with communication systems bonding, but the IBT is still for communications systems only.

Please check our online catalog for information about our IBBZ (zinc) and IBBCU (copper alloy) intersystem bonding terminations, and UL-listed connectors.

And remember, you local inspector or AHJ can provide definitive answers if further questions arise.

Thanks for your question. We hope you find this answer helpful.

Got a grounding electrode, clamp or connector question you’d like to ask? We’ve got answers!

We’ll get back to you with an answer ASAP. And your question could be featured on this page or in our next e-newsletter!

OCTOBER 2019

Q. “I am looking for a copper-bonded ground rod that meets the RUS specification of 13 mil minimum thickness of copper. Is this something available from Galvan?”

Answer:

Absolutely. But to answer the question thoroughly, it should be noted that the Rural Utilities Service (RUS) has fully accepted copper-bonded ground rods with 10-mils of copper plating since April 2015. Prior to that time, the RUS specification called for 13-mils minimum of copper.

Some utilities still prefer ground rods made to the older standard. We are happy to provide both to meet our customers’ needs.

Our trade size 5/8″ (0.555-0.565) ground rods are available in 8-foot and 10-foot lengths with 13 mils minimum of copper coating. The part number for the 8-foot rod is 6258G13. For the 10-foot rod, the part number is 6260G13.

The part numbers for the 10 mil RUS approved copper-bonded ground rod are 6258 (8 foot) and 6260 (10 foot). The 10-mil rod is a little less expensive than the 13-mil rod because there is less copper.

Otherwise, there is no difference in materials or in our process between the two rods. All our copper-bonded ground rods are manufactured in the USA under patent # 6,527,934 and have a uniform coating of either 10 mils or 13 mils of copper metallurgically bonded to a rigid, cold drawn steel core. The ends are pointed and chamfered for easier driving without mushrooming. Each rod is clearly and permanently marked, identifying the manufacturer and displaying the listing symbol for easier inspection.

We also manufacture UL-listed ground rods with 1/2″, 5/8″, 3/4″ and 1″ diameters in copper-bonded, galvanized and stainless steel.

Galvan offers utilities and contractors the widest selection of UL listed and RUS approved ground rods in the industry.

Thanks for your great question! We hope you find the answer helpful.

Got a grounding electrode, clamp or connector question you’d like to ask? We’ve got answers!

We’ll get back to you with an answer ASAP. And your question could be featured on this page or in our next e-newsletter!

JUNE 2019

Q: “My home was built in the early 80’s. I’m having trouble with my television and the cable people (several have come out) all say my house needs better grounding. Does that sound right? Is it something I can do myself?”

Answer:

Yes, bad grounding can cause problems with home electronics. No, you’ll want a qualified electrical contractor to make any necessary repairs or improvements to your grounding system.

A licensed electrician can inspect your electrical system grounding to be sure it is in good condition and complies with the latest edition of the National Electrical Code (NEC) approved by your state.

Codes change. For example, current NEC code requires two 8-ft. ground rod electrodes driven below grade at least six feet apart unless a single driven electrode can be proven to have a maximum resistance of 25 ohms. That was not the case when your home was built. It probably has only one grounding electrode, and it may not be in very good shape.

Like most things, grounding electrodes don’t last forever. There is a possibility your electrical grounding has been compromised naturally by corrosion over the past 30-plus years. Having an electrician update your grounding to current standards with two new 8-foot UL-listed ground rods will make your home safer and possibly improve your television reception, too!

We hope this answer helps. Be safe, not sorry!

Got a grounding electrode, clamp or connector question you’d like to ask? We’ve got answers!

We’ll get back to you with an answer ASAP. And your question could be featured on this page or in our next e-newsletter!

APRIL 2019

Q: “Does the NEC have a requirement for bonding and grounding cable and telephone systems?”

Answer:

Yes, NEC 250.94 requires the bonding of communication systems such as telephone and cable through the use of one of three approved methods, including the Intersystem Bonding Termination (IBT), which is defined as “a device that provides a means for connecting communications system(s), grounding conductor(s) and bonding conductor(s) at the service equipment or at the disconnecting means for buildings or structures supplied by a feeder or branch circuit.”

Code requires that IBTs have the capacity for connection of not less than three intersystem bonding conductors and also have a connection point to accommodate a 6-AWG or 4-AWG grounding conductor that bonds it to the electrical system ground.

Galvan’s UL-Listed IBBZ and IBBCU meet these requirements. Through-hole style connections are provided for up to four system bonding wires, sizes #14 to #4. A lay-in connection for the main grounding conductor accepts sizes #6 to #2.

So, while only one grounding conductor can be connected to one grounding electrode with one grounding clamp, multiple system bonding conductors can be bonded to the GEC through the intersystem bonding bridge. The use of an IBBZ or IBBCU simplifies grounding protection of communications or “other” systems and reduces the hardware needed by installers.

Thanks for the question! We hope this answer was helpful.

Got a grounding electrode, clamp or connector question you’d like to ask? We’ve got answers!

We’ll get back to you with an answer ASAP. And your question could be featured on this page or in our next e-newsletter!

FEBRUARY 2019

Q: “I live in Salt Lake City. Are Galvan ground rods and clamps available near me?”

Answer:

Of course. Galvan’s complete line of UL-listed ground rods, clamps, couplings, connectors, drivers and accessories are available through better electrical wholesalers nationwide. We support all these outlets with 19 strategically placed rep stocking warehouse locations across the country, including one in Salt Lake City, Utah.

Galvan manufactures the most extensive line of UL listed ground rods in the industry, all made here in the USA in our factory in Harrisburg, NC. The line includes copper-bonded, hot dip galvanized, solid copper and solid stainless steel ground rods. Every ground rod we sell that is at least eight feet in length is UL listed.

No matter where you go in the USA, you can stay grounded and connected with Galvan.

Thanks for asking Galvan! We hope you find this answer helpful.

Got a grounding electrode, clamp or connector question you’d like to ask? We’ve got answers!

We’ll get back to you with an answer ASAP. And your question could be featured on this page or in our next e-newsletter!

JANUARY 2019

Q: “How much of an 8-foot ground rod can be left above ground and still pass inspection?”

Answer:

According to the National Electrical Code, none of an 8-ft. ground rod can be above ground. NEC Article 250.53 (G) reads as follows:

“Rod and Pipe Electrodes. The electrode shall be installed such that at least 2.44 m (8 ft) of length is in contact with the soil.”

This means that if you are using an 8-ft. ground rod, all of it must be in the soil and none of it can be above the soil.

The code allows the electrode to be driven at an angle not to exceed 45 degrees or buried in a 30-inch deep trench “where rock bottom is encountered” preventing the electrode to be driven straight down for eight feet. However, all eight feet of the rod must be in contact with the soil.

If the rod is longer than 8 feet, and has been driven to the required depth, the remaining portion can be left above ground only if “the aboveground end and the grounding electrode conductor attachment are protected against physical damage as specified in (section) 250.10.”

Always keep in mind that the Authority Having Jurisdiction (AHJ) has the final determination of what is code compliant. We suggest contacting your local electrical inspector regarding answers to questions specific to your area.

Thanks for asking Galvan! We hope you find this answer helpful.

Got a grounding electrode, clamp or connector question you’d like to ask? We’ve got answers!

We’ll get back to you with an answer ASAP. And your question could be featured on this page or in our next e-newsletter!

NOVEMBER 2018

Q: “Is it NEC code compliant to use a bronze acorn clamp with a galvanized ground rod?

Answer:

If the clamp in question is a Galvan G-5 or SRC, then the answer is yes. However, most other acorn clamps are NOT listed for galvanized or stainless steel ground rods, which is a problem where the code is concerned. NEC 250.70 Methods of Grounding and Bonding Conductor Connection To Electrodes clearly states “Ground clamps shall be listed for the materials of the grounding electrode”.

Galvan has solved that problem. New Galvan G-5 and SRC grounding clamps are UL listed for copper-bonded, galvanized and stainless steel ground rods. They are also listed for rebar (UFER) grounds. The listing includes direct burial in earth and concrete.

The SRC’s UL listing covers use with ½-inch to ¾-inch copper-bonded, galvanized and stainless steel rods, plus ¾-inch “full size” galvanized rods (0.750 – 0.765). In addition, the listing covers sizes #4, #5 and #6 rebar.

The new G-5 is listed for ½-inch to 5/8-inch copper-bonded, galvanized and stainless steel rods, 5/8-inch UL galvanized rods (0.539 to 0.555) and 5/8-inch “full size” galvanized rods ((0.625 -0.640). They are also listed for #4 rebar.

New Galvan G-5 and SRC ground clamps are made in the USA. They meet the Buy American Requirement under Section 1605 of the American Recovery and Reinvestment Act (ARRA) of 2009, and the Buy America Act, United States Codes 23 USC 313 and Code of Federal Regulations 23 CFR 635.410. This solves another problem or creates an opportunity, depending on your point of view.

Thank you for your question. We hope you find the answer helpful.

Got a grounding electrode, clamp or connector question you’d like to ask? We’ve got answers!

We’ll get back to you with an answer ASAP. And your question could be featured on this page or in our next e-newsletter!

JUNE 2018

Q: “Are your stainless steel products 100% from the USA?”

Richard Teebken

Answer:

Yes, Richard, all Galvan ground rods, including our regular and threaded sectional stainless steel ground rods, are made in America and meet Buy American requirements. Our steel grounding plates, threaded and threadless couplings and acorn-type grounding clamps for stainless steel, galvanized and copper-bonded ground rods are made in the USA, as well.

Galvan Industries ground rods are manufactured in Harrisburg, N.C. substantially from articles, material or supplies mined, produced or manufactured in the United States as defined in the Buy American Requirement under section 1605 of the American Recovery and Reinvestment Act (ARRA) of 2009, and the Buy America Act, United States Codes 23 USC 313 and Code of Federal Regulations 23 CFR 635.410.

We are happy to issue BAA certificate letters specifically for and with our American-Made Galvan electrical products.

Thank you for your question and for supporting American industry.

Got a grounding electrode, clamp or connector question you’d like to ask? We’ve got answers!

We’ll get back to you with an answer ASAP. And your question could be featured on this page or in our next e-newsletter!

APRIL 2018

Q: “What’s the difference between bonding and grounding? I’m having a pool built. I am not an electrician and I want to understand.”

Answer:

In simple terms, bonding connects things together. Grounding connects them to the earth.

Bonding is the process by which electrical and metallic components are joined together, usually with a wire bonding conductor, to form a equipotential network. All bonded metal objects will have substantially the same electrical potential, protecting individuals from shock hazards.

Grounding is the process by which the bonded components in the network are connected to the earth. The goal is to direct and dissipate any harmful electrical current safely into the ground.

Bonding and grounding work together. In your situation, electrical components, such as pumps, and non-current-carrying metallic components, such as pool rails, are required to be electrically interconnected (bonded) and grounded to ensure their safety. According to Article 680 of the National Electrical Code (NEC), ALL pool components that might become energized must be bonded and grounded. These include rebar, drains, water inlets, skimmers, ladders, slides, diving boards, underwater lighting, junction boxes, and water circulating/heating equipment.

Galvan offers a full line of the electrical connectors for pool bonding and grounding including the LIC-50S lay-in lug, Type K copper split bolts, Type FLC copper lugs and the JRD pipe clamp for bonding pool steel to rebar. They are available to your pool builder from a local Galvan distributor.

Thanks for your question! We hope you find this answer helpful.

Got a grounding electrode, clamp or connector question you’d like to ask? We’ve got answers!

We’ll get back to you with an answer ASAP. And your question could be featured on this page or in our next e-newsletter!

MARCH 2018

Q: “I have to drive a ground rod on a sloping grade that won’t allow the use of a ladder. Any suggestions?”

Answer:

Galvan’s GRDU Universal Ground Rod Driver may be just the tool you need. It is a safer alternative to hammers or power drivers when installing ground rods or rebar on a steep slope. It is designed for use without a ladder and weighs just 23 lbs. It is Made in the USA.

The driver maintains contact with the rod, giving you more control from beginning to end, including below grade. The weighted steel driver body is made with rubber hand grips for greater comfort, power and control. The GRDU also a very economical solution. You could buy one for a single job or keep one on every truck in your fleet.

Ground rods need to be driven as straight down as possible, and the entire rod needs to be in contact with the earth, so the ability to drive the rod below grade is important. The GRDU is designed to do both these things.

Keep in mind that NEC 250.53(2) requires the use of two electrodes unless a single electrode has a resistance to earth of 25 ohms or less. That means unless you can prove through testing after installation that the resistance to ground is 25 ohms or less for a single electrode, you’ll need to install a second at least six feet from the first. The two must be connected by an appropriately sized grounding conductor and clamps listed for use with ground rods, like the Galvan G-5, SRC or JRD.

Another option for you would the use of grounding plates, such as Galvan GP series, buried a minimum of 30 inches per NEC 250.53.H instead of ground rods. The two grounding electrode rule would still apply, but in some soil conditions or rocky environments, it may be easier to dig two 30-inch holes than to drive two 8-foot rods.

Thanks for the great question! We hope you find the answer helpful.

Got a grounding electrode, clamp or connector question you’d like to ask? We’ve got answers!

We’ll get back to you with an answer ASAP. And your question could be featured on this page or in our next e-newsletter!

FEBRUARY 2018

Q: “Your literature states that your copper-bonded ground rods are UL 467. What is the UL 44DF that’s stamped on the rod?”

Answer:

Galvan’s copper-bonded ground rods are indeed certified to UL467, which identifies criteria important to production of ground rods with this coating type in the electrical market.

Ground rods, like other electrical products, must be submitted to a Nationally Recognized Testing Laboratory (NRTL) and pass rigorous product testing with an acceptable level of performance to become listed or certified. Once a ground rod has achieved certification, the listing agency (eg UL, CSA, ETL, etc) provides the manufacturer with a reference number which must be permanently marked on the rod.

The 44DF is the reference number specifically for Galvan.

In other words, UL467 documents criteria that must be complied with during the testing process, while the 44DF is the ‘reference number’ for Galvan’s certification.

That is why, when you examine our 5/8 x 8 UL copper-bonded ground rod, you will see the following stamped on the rod: GAL 6258 UL LISTED 44DF. This identifies Galvan as the supplier, our part number, the UL logo followed by the word “listed”, and the Galvan reference number, 44DF.

Thank you for your question. We hope this clears up any confusion.

Got a grounding electrode, clamp or connector question you’d like to ask? We’ve got answers!

We’ll get back to you with an answer ASAP. And your question could be featured on this page or in our next e-newsletter!

JANUARY 2018

Q: “I noticed that it says ‘Made in USA’ but I’m emailing to ask if your galvanized steel grounding rods meet FHWA domestic sourcing standards (i.e. manufactured in US). The relevant Federal code is: 23 CFR 635.410.“

Henry Tokar

Ohio Department of Transportation

Answer:

Yes, Henry, Galvan Industries galvanized ground rods do meet the requirements of Federal Code 23 CFR 635.410.

As you know, to be recognized as a US-made product under this regulation, all manufacturing processes must take place domestically. “Manufacturing” is defined any process that modifies the chemical content, physical shape or size, or final finish of a product. Manufacturing begins with the initial melting and mixing, and continues through the bending and coating stages. If a domestic product is taken out of the US for any process, it becomes foreign source material.

To make a long story short, all American-made Galvan ground rods, including our high-quality galvanized ground rods, meet Buy American requirements.

Galvan Industries ground rods are manufactured in Harrisburg, N.C. substantially from articles, material or supplies mined, produced or manufactured in the United States as defined in the Buy American Requirement under section 1605 of the American Recovery and Reinvestment Act (ARRA) of 2009, and the Buy America Act, United States Codes 23 USC 313 and Code of Federal Regulations 23 CFR 635.410.

Plus, every Galvan hot dip galvanized ground rod at least eight feet in length is UL and/or CSA listed. Most competitor’s galvanized rods are not listed at all.

We are happy to issue BAA certificate letters specifically for and with our American-Made Galvan electrical products.

Thank you for your question and for supporting American industry.

Got a grounding electrode, clamp or connector question you’d like to ask? We’ve got answers!

We’ll get back to you with an answer ASAP. And your question could be featured on this page or in our next e-newsletter!

DECEMBER 2017

Q: “Santa’s sleigh flying at such high speeds must build up quite a charge of static electricity, which could lead to communication problems and nasty shocks. How does he deal with that?”

Answer:

You are right. The friction caused by Santa’s sleigh moving through the air will charge the skin of the sleigh, like other high-speed air craft, with static electricity which can interfere with communications and cause potentially dangerous sparks.

We asked Santa your question and found that there are two parts to the answer.

First, all parts of the sleigh have to be bonded together so that they have equal charge or potential. This is done with bonding strips, conductor wires and a few Galvan Type K copper split bolts, providing a low-resistance path for the electrons to travel, and preventing arcing. Bonding components are installed against unpainted metal to ensure a good connection.

Secondly, the reindeer’s antlers act as static discharge wicks (SDWs) which remove electrical charge built up by flight, returning it to the air. Santa’s reindeer trainers keep a close eye on the condition of those antlers. The basic principles of bonding and grounding keep Santa and your presents safe.

Thanks for the great question! We hope the answer is helpful.

Got a grounding electrode, clamp or connector question you’d like to ask? We’ve got answers!

We’ll get back to you with an answer ASAP. And your question could be featured on this page or in our next e-newsletter!

NOVEMBER 2017

Q: “We routinely drive coupled ground rods to depths of 20 or 30 feet. Is there an advantage to either threaded or threadless couplings and rods?”

Answer:

Ground rods are sometimes joined together in order to drive them to greater depth. When driven deeper, resistance is greatly reduced. Generally speaking, doubling of the rod length/depth can reduce resistance by 40%. Having the coupled rods securely attached to each other is very important to the process, but which type of coupling is better is generally a matter of personal preference.

“Sectional” rods have historically been made with threads at both ends and joined together using a threaded coupling. It is traditionally how it has been done and many in the industry hold to that tradition.

During the past 25 years, however, threadless couplings have become very popular for a number of reasons.

During the driving process, a threaded coupling can actually loosen, like when you hit a nut with a hammer to remove it from a rusty piece of equipment. However, with a threadless or compression coupling, the connections become more secure with driving. Threadless couplings also assure a longer-lasting connection, less subject to corrosion and increased resistance to ground due to compromised continuity from one rod section to the next.

The longer-term advantage may be with threadless, but both types work well.

Galvan produces both threaded and threadless ground rods and couplings for copper-bonded and stainless steel ground rods. Couplings for copper-bonded rods come in sizes for 1/2, 5/8, 3/4 and 1-inch rods. Stainless steel rod couplings are available in 5/8, 3/4 and 1-inch sizes. Galvan threadless couplings for hot dip galvanized rods are also available in 5/8, 3/4 and 1-inch. All are UL listed, so you know they are safe and reliable.

Thanks for the great question! We hope the answer was helpful.

OCTOBER 2017

Q: “Most of the electrical contractors in my area use copper-bonded ground rods even though they are more expensive than galvanized. Is copper better than galvanized? Why the cost difference?”

Answer:

As far as the National Electrical Code is concerned, listed copper-bonded ground rods and listed hot dip galvanized ground rods are equal and interchangeable. Both are NEC compliant. The only real difference is the coating.

Both use a steel core coated with either copper or zinc (galvanizing) to prevent corrosion. The differences in cost between the coating materials and the processes involved result in a higher price for copper-bonded rods.

While the NEC says either coating meets requirements, there may be local and regional preferences, as you have noted. These may be based on predominant soil conditions or installlation history. “That’s the way we’ve always done it” is really not a bad reason for choosing one or the other if it’s based on safe, successful history.

The Authority Having Jurisdiction (AHJ) has the final word on what is acceptable in a given area. We suggest contacting your local electrical inspector before changing from the local norm.

Thanks for the great question! We hope you find this answer useful.

Got a grounding electrode, clamp or connector question you’d like to ask? We’ve got answers!

We’ll get back to you with an answer ASAP. And your question could be featured on this page or in our next e-newsletter!

SEPTEMBER 2017

Q: “I have a project where it is impossible to drive an 8-foot ground rod to depth. I hit rock about four feet down. What’s the minimum depth for a ground plate, and will it work as well?”

Answer:

The National Electrical Code (NEC) in Article 250.53(H) requires a minimum depth of 30 inches for a ground plate.

The ability of a grounding electrode like a plate or a rod to transfer an electric current safely back to ground is directly related to the amount of its surface area in contact with the earth. An 8-foot x 5/8-inch UL listed ground rod has a surface area of about 154 square inches. Galvan’s GPGC steel ground plate (shown at left) has 288 square inches of surface area.

The NEC treats ground rods and grounding plates as equals. Either can be effective if installed properly and can be used alone in an NEC-code application if it can be shown through testing to have a resistance to ground of 25 ohms or less. If not, or if you’d rather not do resistance testing, then a second electrode must be installed at a minimum distance of six (6) feet from the first.

This rule is the same for rod, plate and pipe electrodes so you will need to install two ground plates unless you can prove the 25 ohms or less resistance with one.

Always keep in mind that the Authority Having Jurisdiction (AHJ) has the final determination of what is code compliant. We suggest contacting your local electrical inspector regarding any questions.

Thanks for asking Galvan! We hope you find this answer useful.

Got a grounding electrode, clamp or connector question you’d like to ask? We’ve got answers!

We’ll get back to you with an answer ASAP. And your question could be featured on this page or in our next e-newsletter!

AUGUST 2017

Q: “I noticed in your catalog that you offer 10-mil and 13-mil copper-bonded ground rods. Why is that?”

Answer:

Until April 2015, the copper-bonded ground rods used by RUS utilities had to be made to a different specification than those used in the contractor market. UL Listed rods used by contractors have a 10-mil minimum (254 microns) copper coating. However, the RUS specification called for 13-mils minimum of copper. In order to serve both markets, we manufacture copper-bonded ground rods to both standards.

Two years ago, the RUS changed its requirements. The 10-mil minimum coating is now fully acceptable in RUS applications, but some utilities still prefer ground rods made to the older standard. We are happy to provide both to meet our customers’ needs.

There is no difference in materials or in our process between the two rods. All our copper-bonded ground rods are manufactured in the USA under patent # 6,527,934 and have a uniform coating of either 10 mils or 13 mils of copper metallurgically bonded to a rigid, cold drawn steel core. The ends are pointed and chamfered for easier driving without mushrooming. Each rod is clearly and permanently marked, identifying the manufacturer and displaying the listing symbol for easier inspection.

The 10-mil rod is a little less expensive than the 13-mil rod because there is less copper. The 13-mil rod offers a little more protection from damage during driving than the 10-mil rod because there is more copper. A cost/benefit analysis will point to one or the other depending on the user’s particular situation, including soil conditions.

Galvan will continue to offer utilities and contractors the widest selection of UL/CSA listed and RUS approved ground rods in the industry.

Thanks for your great question! We hope you find the answer helpful.

Got a grounding electrode, clamp or connector question you’d like to ask? We’ve got answers!

We’ll get back to you with an answer ASAP. And your question could be featured on this page or in our next e-newsletter!

JULY 2017

Q: “What’s the difference between NEC and NESC requirements for galvanized ground rods?”

Answer:

The National Electrical Code (NEC), which is the basis for most state and local electrical codes, and the National Electrical Safety Code (NESC), which is followed by most utilities, do vary on some shared subjects. One is ground rods. For galvanized ground rods, widely used by utilities, the NESC requires a minimum diameter of .625 inches (5/8″) and length of not less than eight feet. Though it is not required, Galvan’s .625 diameter galvanized ground rod (part # GR6258F) is UL Listed giving the utilities an extra measure of assurance as it relates to the quality of the ground rod.

The NEC allows more flexibility in diameter, with a minimum diameter equal to or greater than 1/2-inch for a listed rod or .625 inches for an unlisted ground rod. That’s because the NEC deems the UL-Listed galvanized ground rod as interchangeable with the UL-Listed copper ground rod. Galvan’s UL-Listed copper and UL-Listed galvanized ground rods both use the same high quality steel core. Only the coating is different. This allows the user to pick a safe, UL-listed rod that best suits the situation in regards to soil conditions, other buried materials nearby, etc.

And the permanantly stamped UL logo near the drive end allows the inspector to know that the rod was manufactured to length and diameter required by the code, even after it is driven.

Thanks for your question! We hope you find this answer helpful.

Got a grounding electrode, clamp or connector question you’d like to ask? We’ve got answers!

We’ll get back to you with an answer ASAP. And your question could be featured on this page or in our next e-newsletter!

MAY 2017

Q: “Can I get an A.R.R.A. certificate on part # 6258, 5/8″x8′ copper-bonded ground rod?”

Shane Hester

Answer:

Yes you can, Shane. Galvan issues certificate letters specifically for and with American-Made Galvan electrical products. Galvan Industries ground rods are manufactured in Harrisburg, N.C. substantially from articles, material or supplies mined, produced or manufactured in the United States as defined in the Buy American Requirement under section 1605 of the American Recovery and Reinvestment Act (ARRA) of 2009, and the Buy America Act, United States Codes 23 USC 313 and Code of Federal Regulations 23 CFR 635.410.

Galvan does not issue certificates without a product purchase, however, to prevent the certificates being used with competitive items not made in the USA. Distributors and contractors should be sure that their certification letters match the products provided so that money allocated for American-Made products actually goes to American-Made products.

Thank you for your question and for supporting American industry.

.

Got a grounding electrode, clamp or connector question you’d like to ask? We’ve got answers!

We’ll get back to you with an answer ASAP. And your question could be featured on this page or in our next e-newsletter!

APRIL 2017

Q: “There seems to be a lot of differences in galvanized ground rods from manufacturer to manufacturer, but copper-bonded rods all look very similar. Why is that?”

Answer:

That’s a great question. At Galvan, we manufacture our UL-Listed galvanized ground rods from the same steel core as we manufacture our UL-Listed copper-bonded ground rods. They perform the same function in the same way. The coating is only there to prevent corrosion.

Galvan’s copper-bonded and galvanized ground rods are both tapered on the drive end so that if there is any mushrooming, the ground rod clamp can be easily installed onto the ground rod. Some ground rod manufacturers do not taper the drive end of their rod. This can create installation issues with the clamp if mushrooming occurs.

The pointed end of Galvan’s UL Listed copper-bonded and UL Listed galvanized ground rods is conical in shape thereby allowing for a problem-free fit into a threadless coupling. Some manufacturers use a nail point on their galvanized rods which could potentially cause problems when installed with a threadless coupling. And, believe it or not, some manufacturers’ galvanized ground rods are not even UL Listed. So, to your point, there are many differences in galvanized ground rods.

At Galvan, your choice of coating doesn’t change the way the rod is made. You get the same quality of materials and manufacturing from Galvan regardless of which coating you choose, and the rods are listed to UL-467 so that you know they meet code. Those are our standards.

Thanks for the question. We hope this answer is helpful.

Got a grounding electrode, clamp or connector question you’d like to ask? We’ve got answers!

We’ll get back to you with an answer ASAP. And your question could be featured on this page or in our next e-newsletter!

FEBRUARY 2017

Q: “I’ve always thought of Galvan as a ground rod manufacturer. When did you get into connectors?”

Answer:

You are right, Galvan has been a U.S. manufacturer of ground rods for more than 50 years, but we expanded our line in 1999 to include connectors, clamps, tools and accessories.

Today, in addition to the industry’s largest selection of U.S.-made, UL-listed ground rods – copper-bonded, hot dip galvanized, solid stainless and solid steel – we offer more than 450 SKUs in 18 other product categories including:

- Ground Rod Clamps

- Intersystem Bonding Terminations

- Water Pipe Ground Clamps

- Ground Rod Drivers

- Bonding & Grounding Connectors

- Insulation Piercing Connectors

- Split Bolts

- Dual Rated Aluminum Mechanical Connectors

- Aluminum Panel Board Connectors

- Aluminum Tap Connectors

- Mechanical Aluminum Splices

- Lay-in Connectors

- Multi-Tap Connectors

- Compression Connectors

- Compression Splices

- Copper Mechanical Connectors

- Oxide Inhibitor

- Compression Tools

Galvan is a major supplier of these items and the highest quality American-made ground rods to the cable television, construction, lightning protection, telecommunications and electric power transmission and distribution markets.

Thanks for the great question!

Got a grounding electrode, clamp or connector question you’d like to ask? We’ve got answers!

We’ll get back to you with an answer ASAP. And your question could be featured on this page or in our next e-newsletter!

JANUARY 2017

Q: “What is the material specification for the steel used in ground rods? Is there an industry standard?”

Answer:

The ANSI-approved NEMA/GR-1 standard established in 2001 requires the steel used in the ground rod core to meet the specifications of ASTM-A370, and have a minimum tensile strength of 80,000 PSI with a minimum Rockwell B hardness of 80. The rod’s steel core is required to be ‘cold drawn‘ to assure enhanced hardness, straightness and dimensional stability.

Galvan’s US-Made listed ground rods meet all these requirements. The listing symbol and our mark on the rod are your assurance that this is the case. BUT, with unlisted, unmarked rods, you never know what – if any – standard was applied. The result may be a rod that bends or an installation that does not meet code.

Complete information about industry specifications for ground rods, couplings and clamps can be downloaded from this Web site. Our specification document covers materials, production and use guidelines for the full line of Galvan copper-bonded, stainless-steel and hot-dip galvanized ground rod electrodes and allied products.

It provides specifications on product characteristics including materials, lengths, finished diameters, coating thicknesses, threads and markings. It also refers to Underwriters Laboratories specification on adhesion, bending and surface evaluation; as well as straightness, color-code identification and packaging. Included are details on threaded and threadless couplings as well as compression and bolted clamps. Download it now.

Remember, it’s not “just a ground rod”. Industry specifications matter in terms of safety and usability.

Got a grounding electrode, clamp or connector question you’d like to ask? We’ve got answers!

We’ll get back to you with an answer ASAP. And your question could be featured on this page or in our next e-newsletter!